DeviceNet Diagnostics – indentify issues before they disrupt productivity

Despite the tendency to implement industrial Ethernet on many new production systems, many industries have a large installed base of DeviceNet networks that will operate for many years to come. Once properly installed, and commissioned (with verification), DeviceNet has proven to be reliable for extended periods. So why worry about DeviceNet diagnostics? There are a few common challenges with DeviceNet:

- Network changes, where additional power demands and data traffic were not fully taken into account. This may include incorrect wiring of termination resistors (or too many) at the end of the trunk line.

- Media wear and tear, which often occurs in production systems where there is high vibration, moisture or ambient temperature.

- Configuration issues or non-conformant devices.

Can we wait for one of the above issues (as well as others) to cause DeviceNet to affect production? The obvious answer would seem to be NO, yet many users of DeviceNet do take unnecessary risks like this.

How can we be more proactive in maintaining DeviceNet?

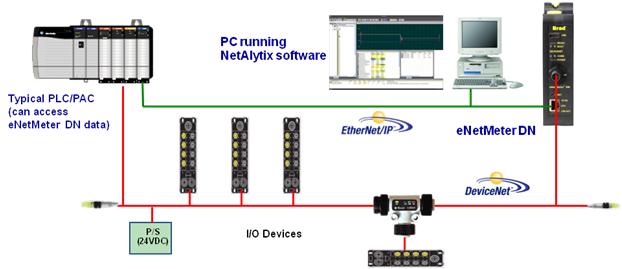

Passive, on-line diagnostic tools for DeviceNet include hardware like the eNetMeter™ DN and complementary software called NetAlytix™. Together, these tools allow a network baseline to be archived during initial system verification for later comparison to real-time data. As network data deviates from norms established by ODVA, corrective action can be taken before the network becomes inoperable.

Typical DeviceNet System with Proactive Approach to Diagnostics: