Flexible 3D Circuits Power Medical Devices

As populations age in developed countries, demand for healthcare is growing and medical practitioners need new ways to deliver care more cost effectively. Many are turning to downsized mobile-monitoring, therapeutic, and diagnostic devices. Flexible printed circuits offered by Molex are often used in these compact medical devices, which require high signal speed, more efficient power distribution, and space-saving designs. Proven flex circuit technology has migrated from consumer electronics into medical devices such as insulin pumps, wearable patient monitoring devices, portable defibrillators, and CPAP machines (used to treat sleep and breathing disorders).

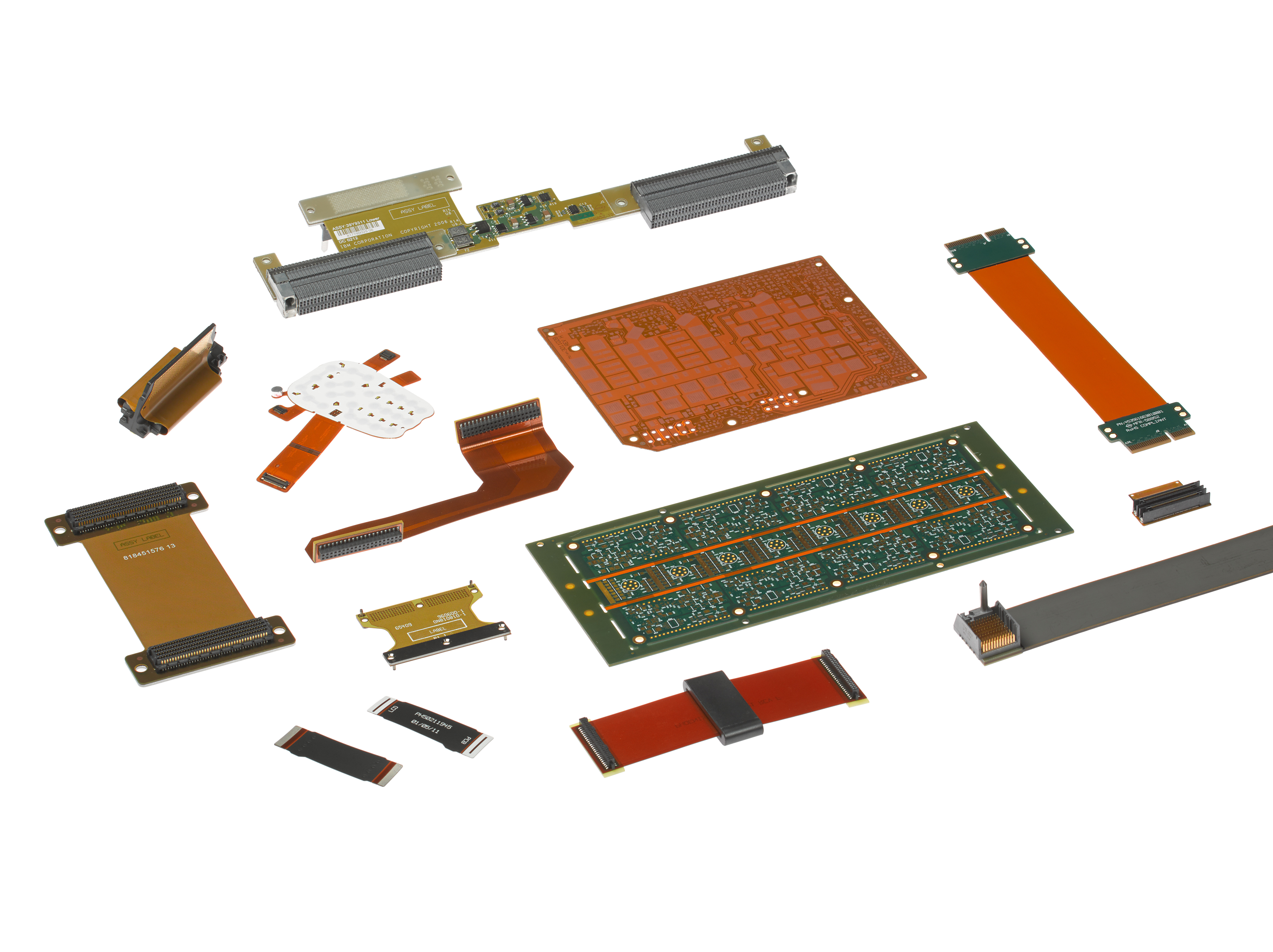

As medical devices shrink, circuitry in these devices must also be scaled down. Flex circuits are ideal for tightly packed architectures and can make any product lighter, improving patient mobility and comfort. Unlike rigid circuit boards, which only allow circuit traces in the X and Y plane, flex circuits can be routed along curved surfaces and in multiple directions on any axis. Additionally, using features like blind and buried vias helps retain flexibility in these smaller devices.

Flex circuits allow simpler, more reliable electronic interconnection. The polyimide material used in their fabrication dissipates heat better than standard PCB materials. As a result, the flex circuit requires less cooling, which can be critical in small systems with low airflow. Additionally, these materials have closely matched thermal expansion rates, which make them more reliable in hot and cold temperature extremes.

As medical technology expands, digital connectivity will create new business models that help reduce healthcare costs. It’s clear that flexible circuits will play a key role in that process.

This blog is based on an article originally published in Medical Design Technology Magazine (December 2015)