Modular Connectivity Offers Strong Advantages

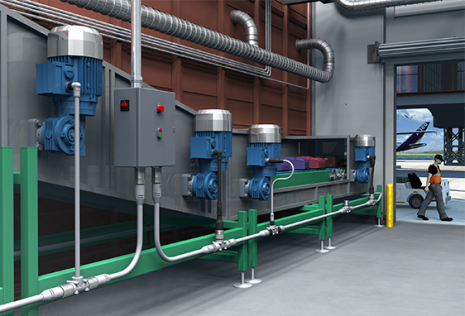

Traditional machine hardwiring involves a virtual maze of wires and cables. In modern machine setups, electrical, signal and data contact points can number into the hundreds for complex operations or multifunctional machines.

By contrast, modular connectors provide excellent mechanical stability, eliminate labor-intensive wired installation in the field, and simplify routine testing and maintenance, especially when machines are in tight spaces or remote plant locations. Technicians can quickly disconnect devices using cordsets with custom configurations and colors, and plug directly into portable testing equipment.

Return on investment for modular connectors can come from:

- Reduced labor and commissioning time for machines, robotics, and assembly lines.

- Significant reduction in electrical commissioning time and total installed cost of machines.

- Highly reliable performance, IEC standardization, and NFPA-79 safety conformance.

- Faster, easier handling of maintenance and repair for higher productivity and less downtime.

- The flexibility and scalability to configure, modify, or expand machines and assembly lines as demands or operations change.

Several modular connector sizes and styles have been specifically designed to address the tough requirements of harsh industrial machine applications and processes. Some of the more common ones include:

- Heavy-duty connectors (HDCs): Liquids, dust, and other contaminants can make their way into the connector housing. Leading to outages and downtime. HDCs are built to deliver years of uninterrupted performance in demanding applications.

- High-power M-Series connectors: Delivering exact industry specifications, M-series connectors ensure compatibility with other component suppliers, industrial-machine OEMs, and system layouts.

- M12 connectors: About 80% or more of the connectors used in machine applications are a variant of M12. It offers the best balance between size, performance, and handling.

- Hybrid connectors: Hybrid connectors in a small build size are based on a circular M12 threaded-coupling design. Increasingly, M12 connectors are being used for conductive and optical sensors, and coded for Ethernet, PROFINET, and other active component bus connections to the programmable-logic-controller (PLC) backbone of industrial machinery and automation platforms.

In harsh industrial environments, modular connectors more reliably withstand heavy use and exposure. Quick-disconnect power and signal connectors and cordsets are factory molded and constructed of crush-resistant material to easily replace machine hardwiring.