SFP(+) to cool or not to cool?

With SFP cages comes always the question whether cooling is necessary or not. There is no clear answer this question. Mainly because there are several parameters which have to be taken into consideration:

- The heat dissipation of one SFP insert can go from zero (copper cable) to approx. 2 watts (when using a twin bi-directional LC insert)

- The equipment practice may be a rack with vertical daughter cards or a pizza box with only a main board or with additional mezzanine cards on top

- The number of ports on a daughter card/mezzanine board

- The density of the ports, whether these are single cages with space in between, ganged cages, or stacked and ganged cages

- The airflow in the system, which is always bottom up in a rack, but it may be different in a pizza box (East->West or Rear-Front)

- The ambient temperature (fan supported approx. +40°C), the maximum temperature of the insert (typically +70°C) and the air flow speed

- Last but not least the “swelter effect” e.g. the first SFPs are heating up the ones at the end of the airflow

We at Molex did a lot of simulations in our thermal labs to understand the results of the above parameters. However, still we do not have a universal recipe to have a black and white solution for the problem. A few guidelines may help. As long as we are talking single cages with space in between, we are on the safe side if the dissipated heat is below one watt per insert. When you start ganging these cages, it is still no problem, assuming you have a copper ground plane underneath the inserts that distributes the heat away. At the moment you are above one watt per insert, care should be taken, especially when ganged SFP cages are your free choice or forced decision. Investigating the configuration of a fully SFP-loaded front panel with inserts above 1.5 watts heat dissipation each insert, we immediately recognized we have to cool the inserts. The first hurdle was to find a good thermal connection between the insert and the heat sink. Only QSFP inserts are designed from the beginning to have a flat and smooth surface on top to have an intimate contact to a heat sink. SFP inserts do not always have this and – even worse – some inserts have the manufacturing label on top, which is not a good heat conductor. You may improve the situation with conductive heat cushions, but the thermal contact is questionable.

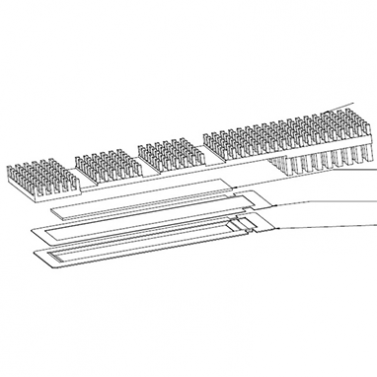

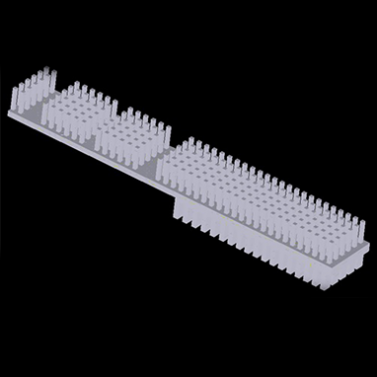

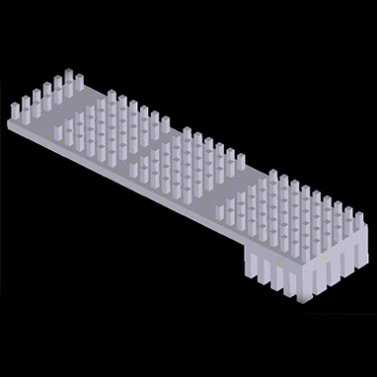

The second hurdle was – under a defined insert with a defined heat cushion – to select the right heat sink in the given environment. The environment was a rack with vertical daughter cards and 24 ganged SFP ports (4 cages each 6 ports).

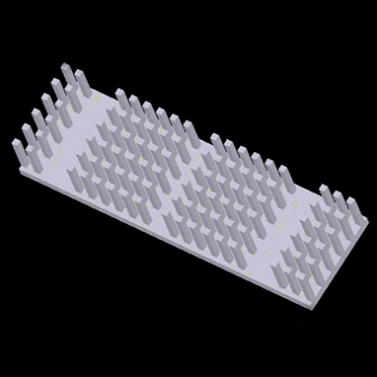

Knowing the height of only 15,2mm above the board, it was clear that a heat sink on top of the SFP cages just blocks the airflow, which is worse than using no heat sinks. The heat sinks must have fingers (no ribs) to create turbulences and get a better thermal conductivity to the air. Finally, we decided to go for “rucksack” heat sinks since a lower profile with a rucksack is more efficient than a higher heat sink just above the cages. We tested several heat sink configurations and found the lower profile longer rucksack as the best performer. However, even with the extended rucksack we had to apply a baffle in order to squeeze the airflow onto the rucksack area, which is shown on the sketch “Rucksack with baffle”

Last but not least, a heat sink comparison matrix was created which showed clearly: a) Heat sinks are sometimes worse than no heat sinks b) Without a baffle, the airflow bypasses the heat sink area and airflow is in vain c) More baffles do not improve the cooling effect d) Most critical is the “swelter effect” in an arrangement as simulated; the lower SFPs heat up the upper SFPs when airflow is not controlled

Molex is offering a large variation of cages for SFP, QSFP and CXP. We investigated, simulated and verified thermal issues with stacked and ganged configurations of SFP and QSFP as we foresee a wider usage of cages in the industry. Not only with heat dissipation from fiber optic transceivers, but also with dissipated heat from active copper cables where equalizers are integrated into the cable plugs.